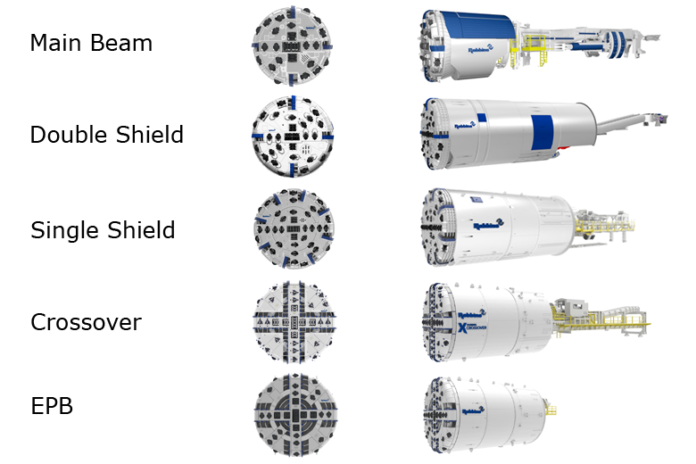

Tunnel Boring Machines aren’t all the same, they have different designs meant to meet specific needs depending on the type of tunneling being done.

Though we often refer to TBM’s as one size fits all, today we wanted to take a look a five different types of Tunnel Boring Machines made by The Robbins Company to explore what they do and how they are used to tackle different tunneling scenarios.

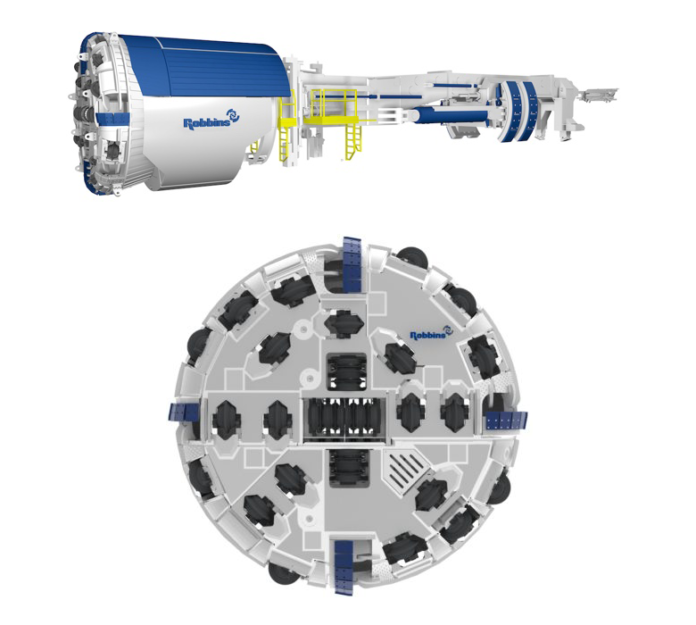

1. MAIN BEAM

A Main Beam TBM is great for digging through hard rock. The Robbins company states that if you want to drill through hard rock in the shortest time possible, then the Main Beam machine is the way to go.

The cutter-head is the same size as the tunnel diameter, and the machine works by thrusting disc cutters into the rock while the cutter-head rotates.

The combination of high thrust and rotation chips away at the rock allowing the machine to advance with ease.

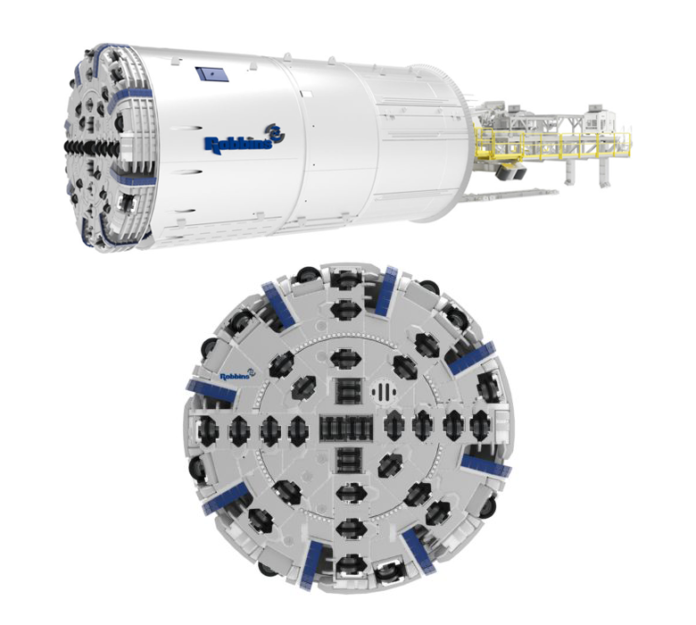

2. DOUBLE SHIELD

A Double Shield TBM was invented by the Robbins Company in 1972 as a way to safely take on tunneling projects that pass through fractured rock, something that could not have been done in the past.

It consists of a rotating cutter-head which is mounted to the cutter-head support, followed up by three shields.

A tail shield, a gripper shield, and a telescopic shield which slides within the larger outer shield.

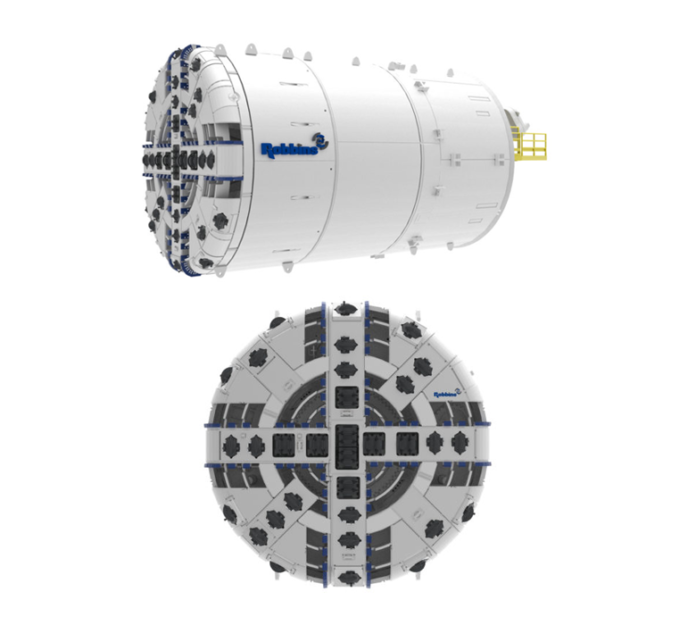

3. SINGLE SHIELD

Single Shield TBM’s are ideal for projects where you have large sections of broken ground to bore through.

Because broken ground is a safety risk to any boring project, it is important that you use a single shield boring machine, as it has a shield that protects workers from broken rock until tunnel lining can be safely installed.

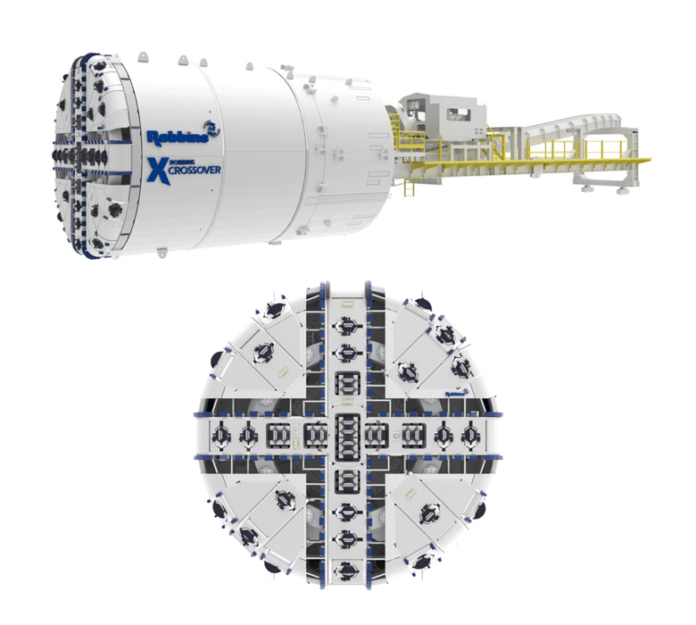

4. CROSS OVER

Crossover TBM’s are primarily used for projects that have a wide range of geological features to dig through.

If a project includes sections of hard rock, soft ground, or boulders then a crossover machine is the best option.

With many interchangeable parts that meet various needs throughout a project, Crossover machines are the go to solution for projects that would normally require multiple machines.

5. Earth Pressure Balance

Earth Pressure Balance or EPB’s for short are designed for operation in soft ground conditions containing water under pressure.

EPB’s have an articulated shield that is sealed against incoming water pressure, and monitor and control the the pressure inside the cutter-head to chamber in order to achieve balance with the pressure in front of the cutter-head – hence the name “earth pressure balance”.

I had work with Herrenknecht EPB Machine for Underground Metro rail Project.

but can you please elaborate or explain about other type of TBMs apart from its make?

Heard rock TBM, open shield, Sully TBM etc.